Oils sludge is derived from drilling, exploration, and the process of refining different oil resources. It is made up of sludge, water, and oil which can result in environmental pollution when it is not processed properly. However, oil sludge contains an abundance of oil which creates favorable income opportunities. These are the reasons why many investors are buying oil sludge pyrolysis plant.

Options Available With Oil Sludge Treatment Plant

– Oil sludge treatment is inclusive of an automated feeding system. It utilizes a direct-condensation technique which assists with helping to cool gases into a liquid. All the exhaust gas and wastewater is processed inside a machine which eliminates environmental pollution.

– The oil sludge recycling plants come with an automated warning device and a pressure gauge which ensures optimal safety during operations.

How Does The Pyrolysis Plant Assist With Treating Oil Sludge

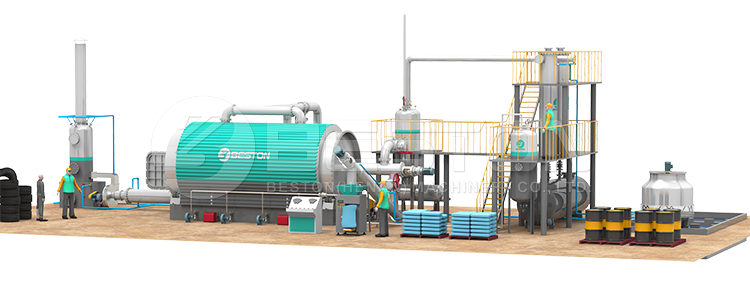

The oil sludge that is created as a by-product through the process of oil refinery and drilling which is also made up of a mixture of oil and water. The pyrolysis plant for oil sludge assists with separating the sludge and water from the oil which results in an oil product that can be used again. The pyrolysis plants are successful in producing fuel oil of high-quality. The oil sludge pyrolysis plants are made up of a hydro-seal, pyrolysis reactor, oil tank, oil condenser, and a de-casting system.

Design Of An Oil Sludge Treatment Plant

The main components associated with exhaust gas which cannot be liquefied includes alkanes class C1 and C4, which when directly burned poses a significant danger. The oil sludge pyrolysis machine is designed in such a way that the gas is first passed through a water seal which is contained in the first sealed device before the gas is used in the form of fuel. The gas is then sent into the gas burner which is contained in a second safety device.

– The hydro-seal in these systems serves the purpose of stopping the flames from burning back and it removes impurities and sulfur which results in clean desulfurization gas.

– These machines also include an advanced pressure and thermometer gauge which performs the function of checking on the pressure and temperature throughout each operation.

– This machine also utilizes a third-generation method of heating which combines exceptional advantages of indirect and direct heating which guarantees a safe operation

The oil sludge pyrolysis plant comes in 3 different types which include the fully-automatic pyrolysis plant, semi-automatic pyrolysis plant, and the batch pyrolysis plant. The ideal plant to match up to your requirements will be based on your budget and your allowance. The crude oil sludge pyrolysis plants have become popular as a highly profitable business opportunity. It is also one of the best ways to safely process oil sludge which is a product that is harmful to the environment. Converting oil sludge into a number of useful materials like organic compounds of a low molecular weight along with carbonaceous residue through the process of pyrolysis solves the issue of disposal and promotes resource utilization.