If you see the term waste tire to diesel plant, you may be wondering exactly where the diesel part comes into play. Many people know all about the pyrolysis process, but they have no idea that they can actually make diesel fuel from the waste rubber. It’s an interesting proposal, and you’re going to need an extra oil distillation machine.

It can be done, however, and it can be quite the profitable endeavor. You can also simply make gasoline from the pyrolysis oil. The oil in general accounts for approximately 40 to 50 percent of what you are going to generate from recycling the waste rubber. The rest is going to amount to carbon black, also about 40 percent, and then there is the steel and gas.

Keep in mind that you’re not going to want to convert all of the pyrolysis oil that you get from the process. That’s because you can save some of it back to actually power the waste tyre oil extraction machine, saving you money during this operation. You want your machine to run for free, so be sure to save some of that oil. You can also use the hydrocarbon gas for the same purpose.

You are going to have to learn more about how to convert the pyrolysis oil into diesel fuel. You might actually want to convert some to diesel and the rest to gasoline, depending on what your needs are. Maybe you even plan to use some of that fuel yourself, too, vs selling it all.

Profits can be derived from in-house savings, too. You use that fuel to save on energy costs, and your recycling efforts are covering more bases. You’re still going to net carbon black, too, which is a substance that is in high demand. You can sell the carbon black, and you can use or sell the recycled steel, too. Everything is profit once you pay that machine off.

You’re wondering for sure how much the tyre to diesel plant is going to cost you. That is a good question that should be answered like this. There are a wide range of prices, and manufacturers like to give personal quotes after you fill out contact forms. These are heavy duty machines, and they are looking for serious inquiries.

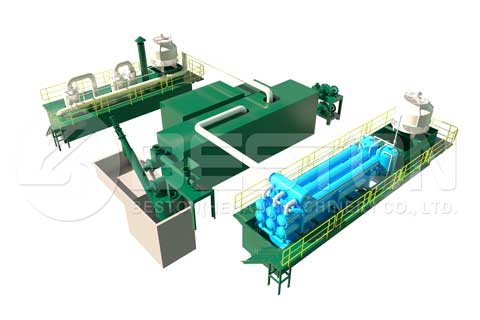

Then there is the fact that there are different sizes and types of these plants. A continuous tyre pyrolysis plant is going to run you more than a batch plant. A larger capacity machine is going to cost more than a small scale pyrolysis plant, too. Keep that in mind when you are evaluating your own needs and speaking with manufacturers.

Also keep in mind that you might spend less if you purchase a pyrolysis machine from an overseas manufacturer. It’s a good tip to go on for sure. See where it leads you, and then you can lock in that discount. You want to get a good deal because the sooner you pay it off with your recycling efforts, the sooner the profits start to stack up.

Visit https://www.bestongroup.com/ if you want to know the technology we use to manufacture the machine.