Choosing the correct pyrolysis plant cost for your business requires a thorough understanding of multiple factors that influence the price. As tyre pyrolysis has become increasingly popular for converting waste tires into valuable resources like fuel oil, carbon black, and steel wire, it’s essential to make an informed investment. This article explores how to assess the true cost of a tyre pyrolysis plant, factors that affect pricing, and how to select reliable manufacturers for maximum return on investment.

Understanding the Baseline Cost Components

A tyre pyrolysis plant cost generally includes several primary components:

- Plant size and capacity: Higher-capacity plants typically cost more but can handle more waste per hour, potentially boosting profitability.

- Technology and design: Continuous pyrolysis systems, while pricier, provide higher efficiency and often offer better fuel yield compared to batch systems.

- Auxiliary equipment: The cost can also rise based on additional components like condensers, coolers, and gas recycling systems, which enhance plant efficiency and environmental compliance.

When budgeting for a pyrolysis plant, it’s essential to factor in these components, as they form the core of any initial investment.

Key Factors Influencing Pyrolysis Plant Cost

1. Plant Type and Automation Level

Tyre pyrolysis plants come in batch, semi-continuous, and fully continuous configurations. Batch plants, generally the most affordable, require periodic feeding and discharge, which can limit processing efficiency. Fully continuous plants, on the other hand, are designed for large-scale operations and can operate 24/7, albeit at a higher cost due to complex automation systems. Semi-continuous plants offer a middle ground with moderate efficiency and cost.

Choosing the plant type based on operational needs helps avoid unnecessary spending. For businesses with high waste tire availability and processing demands, a continuous plant may provide better long-term returns despite its higher initial cost.

2. Material Quality and Durability

Durability is crucial in tyre pyrolysis equipment, as this plant operates under extreme temperatures and involves corrosive chemicals. High-quality materials, such as heat-resistant steel, increase both the longevity and safety of the equipment, though they may increase upfront costs. Investing in well-made equipment minimizes long-term maintenance expenses, making it a prudent option for those looking for a lower total cost of ownership.

3. Manufacturer Reputation and After-Sales Service

Working with reputable tyre pyrolysis plant manufacturers often leads to better outcomes, as they provide reliable equipment and comprehensive after-sales support. When evaluating a manufacturer, consider their industry experience, customer reviews, and the availability of warranties. Quality after-sales services, such as installation support, training, and spare part provision, also contribute to cost savings over time. Manufacturers with strong reputations are more likely to supply durable, well-tested equipment, reducing the likelihood of operational downtime.

4. Compliance with Environmental Standards

Environmental compliance is becoming more stringent in waste processing industries, and pyrolysis operations are no exception. Some pyrolysis plants come equipped with advanced gas recycling and filtration systems to meet emission standards. While these features increase the plant’s cost, they may be essential in regions with strict environmental regulations. Failure to comply with these standards could lead to fines or operational shutdowns, so it is often cost-effective to invest in a compliant plant initially.

5. Installation and Operational Expenses

Besides the upfront cost, consider the installation and operational expenses associated with running a pyrolysis plant. Installation can involve significant labor and infrastructure, including foundation building, electrical setups, and piping. It’s crucial to account for these expenses, as they can be a substantial portion of the project’s total cost.

Operational expenses include energy, labor, and maintenance. Continuous plants, for example, generally have higher power requirements but lower labor costs due to automation. Estimating these expenses helps you gain a clearer picture of the total cost beyond the initial investment.

Selecting Reliable Manufacturers: Key Considerations

Partnering with reliable manufacturers can substantially impact the success of a pyrolysis venture. Here’s what to consider when choosing a manufacturer for your tyre pyrolysis system:

- Technology and Innovation: Look for manufacturers who emphasize technological advancements and have a proven track record. This often indicates a commitment to efficiency and durability.

- Transparency in Pricing: Reputable manufacturers will offer transparent pricing with clear details on what’s included in their pyrolysis plant cost, helping avoid hidden fees.

- Documentation and Certification: Ensure the manufacturer provides proper documentation and certifications, as these reflect their adherence to safety and quality standards. Certification can also simplify obtaining permits and approvals.

- Customer Support: Comprehensive customer support, from installation guidance to troubleshooting, is critical. Choose a manufacturer known for reliable support to ensure smooth operations and timely issue resolution.

Balancing Cost with Long-Term Value

While the initial pyrolysis plant cost can seem high, focusing solely on price may not yield the best results. Evaluating the plant’s efficiency, durability, compliance, and manufacturer support ensures you invest in a solution that aligns with your business needs. A higher upfront cost with reliable features may offer greater long-term value, especially for high-capacity or continuous operations that process large volumes of tire waste.

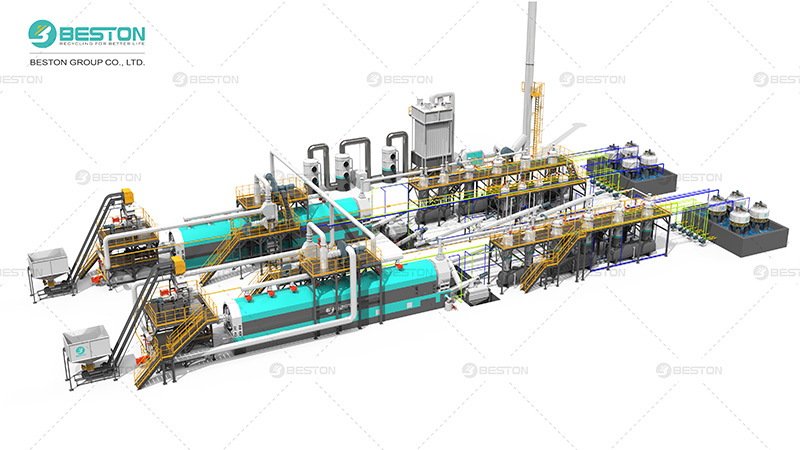

Investing in a well-chosen tyre pyrolysis plant not only provides economic returns through valuable by-products but also promotes sustainable waste management practices. Welcome to consult the Beston Group for tire pyrolysis equipment.