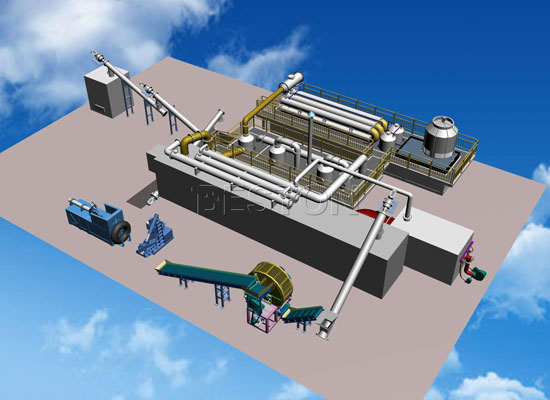

As you start looking at the pyrolysis machines available to you, it’s important to note that there are two different types of plants. There is the batch pyrolysis plant and the continuous pyrolysis equipment. Additionally, there are quite a few manufacturers out there, and you will find a variety of models to choose from. In this case, you’re going to be looking solely at continuous pyrolysis plant that operate 24/7.

First, let’s look at what separates these continuous pyrolysis plants from the batch machines. The continuous plants require less manpower, and they operate constantly as mentioned, 24/7. They are more expensive, yes, but they can process a whole lot of waste rubber, plastic, biomass and sludge oil in one day. You can imagine what that means for turning a profit over the years.

The advantages are clear, but what else do you need to know about the pyrolysis plant? You’re making plans to recycle the waste materials you have on site. When you do that, what are you going to do with the products that come out the other end of the machine? You first need to know what those products are. They are pyrolysis oil, carbon black, recycled steel and hydrocarbon gas. Visit the experienced pyrolysis plant suppliers to get good machines.

Let’s begin with the pyrolysis oil. It can be sold outward as is, which means you can generate profit if you know which companies want to take it off your hands. It can also be used in an oil generator for electricity purposes. Did you know that it can also be refined into gasoline or diesel fuel? You need oil distillation equipment to get the job done.

Additionally, the pyrolysis oil can be used to help heat up the reactor for the pyrolysis machine, too. In other words, the pyrolysis oil is fuel for the plant, and that means it runs itself. That is quite a few uses for the oil. What about the carbon black?

Carbon black is able to be sold, too, and many businesses would be interested in buying the substance from you. It is used to make all kinds of products. Not only can it be sold, but it can be reprocessed as well for a color master batch. It can also be reprocessed into coal, too. That’s what all you can do with the carbon black.

The last byproduct is the hydrocarbon gas or combustible gas. You can store the gas for heating, and like the pyrolysis oil, it can heat the reactor for the machine, too. That’s what all you can do with the products you net from recycling process with continuous pyrolysis equipment. You certainly stand to make some money if you set up a continuous pyrolysis machine at your facility. Go on www.bestonturkey.com.