When it comes to biochar production, selecting the appropriate biochar production equipment is a critical decision that can significantly impact the quality and efficiency of your biochar production process. With various options available in the market, each designed to handle specific feedstock and operational requirements, making an informed choice is paramount.

1. Understanding Your Feedstock

The first step in choosing the right biochar production equipment is understanding your feedstock. The type of feedstock you plan to use, whether it’s wood, coconut shells, or other biomass materials, will greatly influence your equipment selection. Different feedstock may require specialized machinery to achieve optimal results. For example, if you are working with coconut shells, consider investing in coconut shell charcoal machinery designed to handle this specific material efficiently.

2. Production Capacity

Assess your production needs carefully. Determine the volume of biochar you intend to produce on a regular basis. Equipment capacity varies widely, so it’s essential to choose a machine that can meet your production requirements without overloading or underutilizing it. Be mindful of future scalability as well, as your production needs may change over time.

3. Pyrolysis Technology

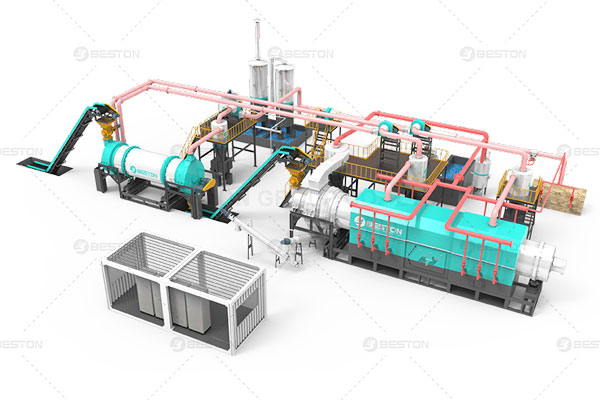

The heart of biochar production is the pyrolysis process, where organic materials are heated in the absence of oxygen to produce biochar. There are various pyrolysis technologies available, such as slow pyrolysis and fast pyrolysis, each with its advantages and limitations. Consider the specific characteristics of your feedstock and the desired biochar properties when selecting the appropriate pyrolysis technology for your wood charcoal making machine.

.

4. Emission Control

Environmental regulations are becoming increasingly stringent. Ensure that the equipment you choose complies with emission control standards in your region. Look for advanced systems that minimize emissions of harmful gases, particulate matter, and volatile organic compounds (VOCs) during the pyrolysis process.

5. Energy Efficiency

Energy costs can significantly impact the overall operational expenses of your biochar production. Opt for carbonizer machine that incorporates energy-efficient features, such as heat recovery systems and insulation, to minimize energy consumption. This not only reduces costs but also makes your operation more environmentally friendly.

6. Automation and Control Systems

Modern biochar production equipment often comes equipped with advanced automation and control systems. These systems not only enhance operational efficiency but also provide better control over the pyrolysis process, ensuring consistent and high-quality biochar production. Look for equipment that offers user-friendly interfaces and remote monitoring capabilities.

7. Maintenance and Durability

Investing in durable and easy-to-maintain equipment is a wise choice. Consider the maintenance requirements of the equipment and the availability of spare parts. A reliable charcoal making machine should be designed for longevity and minimal downtime.

8. Cost Considerations

While it’s essential to focus on quality, budget constraints are also a crucial consideration. Compare the initial purchase price, operational costs, and expected return on investment (ROI) of different biochar production equipment options. Keep in mind that long-term benefits, such as reduced energy costs and increased production efficiency, can outweigh the initial investment.

9. Safety Features

Safety should always be a top priority in any industrial operation. Ensure that the equipment you choose is equipped with safety features and mechanisms to protect operators and prevent accidents. This includes safety interlocks, emergency shut-off systems, and proper ventilation.

10. Supplier Reputation

Lastly, research and choose a reputable supplier with a track record of delivering reliable and high-quality biochar production equipment. Read customer reviews, request references, and inquire about warranties and after-sales support. A trusted supplier can provide valuable guidance and support throughout the equipment selection and purchasing process.